Automated inspection is usually used to replce human inspection in industrial manufacturing companies. Automated inspection overcomes many of the limitations of manual inspection systems. In manufacturing, visual inspection errors take one of two forms. The first is the missing of an existing defect. The second is the incorrect identification of a defect. Misses lead to a loss in quality while incorrect identifications result in unnecessary production costs and overall waste. These errors are often traced back to the undependability of human vision alone, imprecision of eyesight, and cost of labor.

Automated inspection systems typically surpass the standard of manual inspection. Machine vision surpasses human vision in quality and quantity measurements because of its speed, accuracy, and repeatability. Machine vision systems can find object details too small to be detected by the human and inspect them with greater reliability.

Machine vision systems can also go beyond human visual acuity. Machine vision can view in the ultraviolet, x-ray, and infrared regions of the spectrum. On production lines, machine vision systems can inspect hundreds or thousands of components per minute.

How is an automated inspection system implemented in manufacturing equipment

AI doesn’t require a lot of physical equipment. Hardware only requires a feeding system, an optical system, and a separation system. But, the software is robust. It requires advanced image analysis algorithms and heavy programming. The systems are often trained on thousands of images to detect meaningful deviations from the “standard” appearance.

AI and machine vision are taking over mundane and complex tasks like inspections. This lets humans focus on more sophisticated tasks. Costs of AI are forecasted to drop as efficiency increases. Machine vision and deep learning will also be an integral part of Industry 4.0 as manufacturers look for new levels of efficiency and productivity.

About Shenzhen Sipotek Technology Co., Ltd

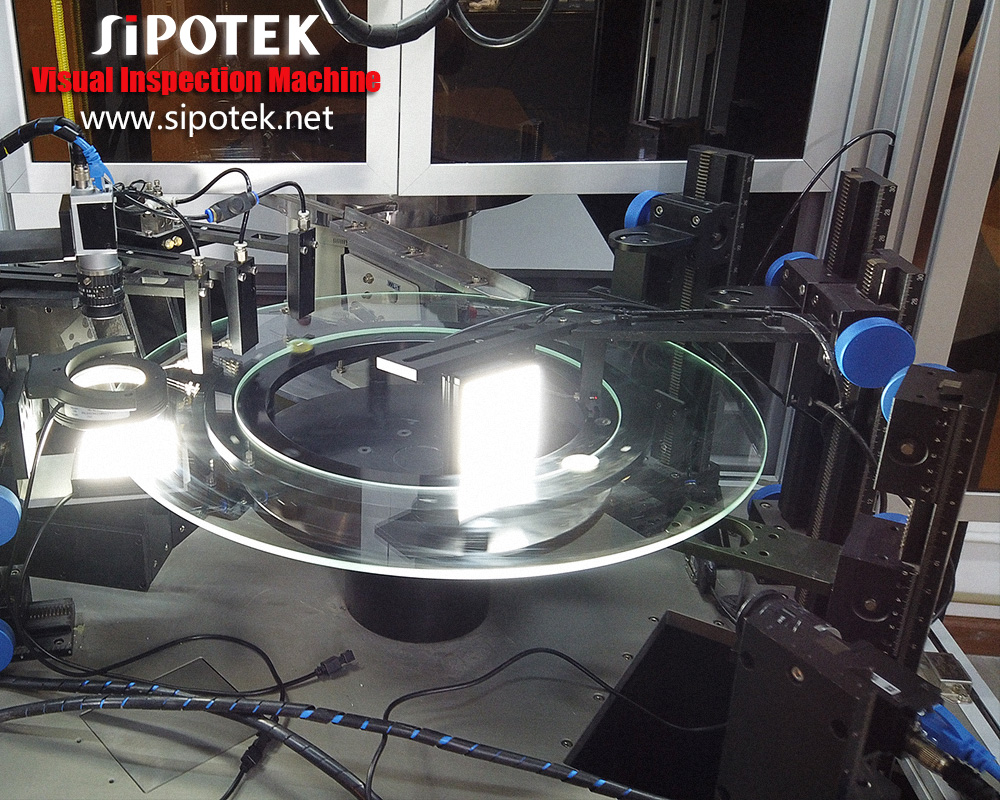

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: Suzy Su

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-18666216027

Email: [email protected]

Website: http://www.sipotek.net/machines/