The vision inspection automation process contains five mechanisms working when an inspection task is begin. It contains input, carrying input, inspection, data processing and output. Input is the firs place the items be put into a special bin. For most of the solutions, vibratory bowl feeder is the perfect option. The vibrating plate is an auxiliary feeding device for automatic assembly or automatic processing machinery. It can arrange various products in an orderly status and send them to the subsequent station position, plate surface, base, clockwise or controller. It was made of aluminium alloy with all-in-one design.

Sipotek Visual Inspection Machine 34

The input mechanism is used to transport the products in the vibratory bowl feeder to next station. The mechanism is usually a straight line on which the products will be gone through one after one in orderly manner.

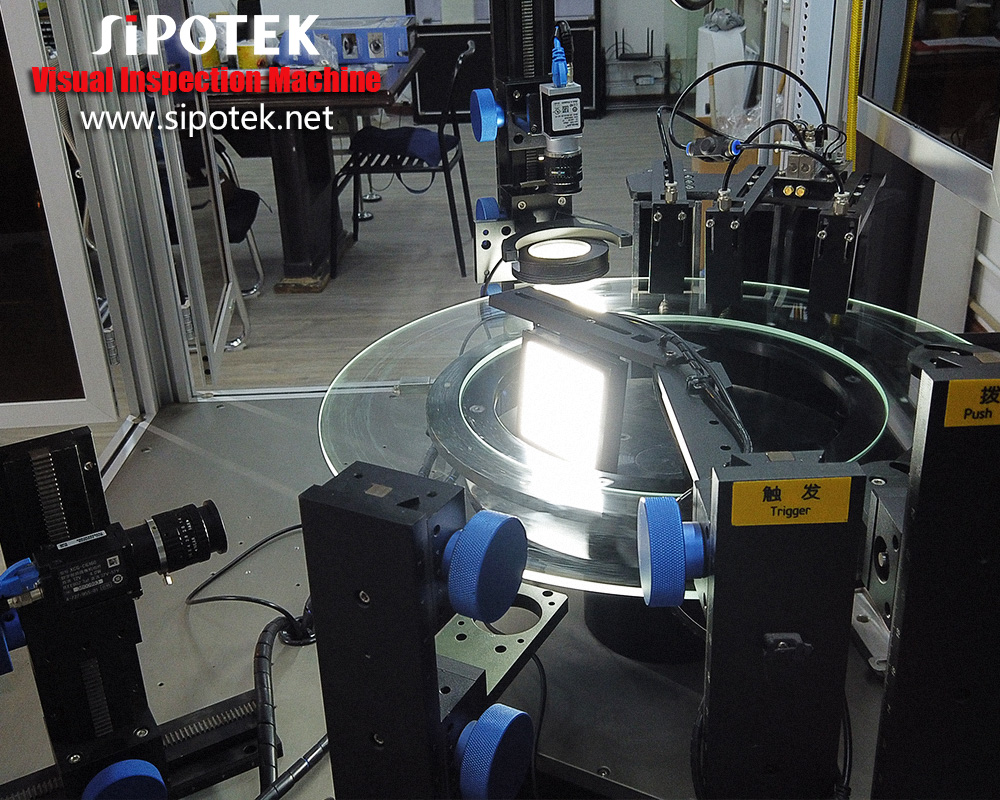

The glass rotary mechanism is made by transparent glass. It’s the inspection stationary of a vision inspection machine. Products carried by the input mechanism will directly come onto this glass plate. There are two designs of the rotary glass, the common one with a round edge, and a slotted one with slots on the edge.

Sipotek Visual Inspection Machine 36

The inspection process begins when the products are appearing on the glass plate. The images of the products will be captured and transmitted to digital signal.

Result processing is the most import process during vision inspection. All results will be shown on the screen. The images will show different sides of the products, such as top and bottom. If defects are found, NG will shown on the control interface.

The simulated image is a continuous point to point composition. Digital images are composed of discrete points, except that the distance between the points is not perceived by our eyes.

A digital image is digitized by an analog image and that is pixel-based and can be stored and processed by a digital computer or digital circuitry.

The output is where he products being sorter and rejected. There different rejections such as air valve blowing. When the product was recognized as negative, a instant trigger will happen by the valve, and a very quick blowing will reject out the unqualified to a specific bin. The ejection method is optional and can be as customer’s oriented.

About us

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186 1718 2707

Email: [email protected]

Website: http://www.sipotek.net/machines/