Shenzhen Sipotek Technology Co., Ltd. is a professional automatic visual inspection machine ,automated vision inspection system,industrial machine vision camera,automated optical inspection machine ,optical sorting machine manufacturer from china with low cost and high quality.

Automated optical sorting can be used to separate different grades of glass, paper, plastic and aseptic (Tetrapak) containers from a waste stream or from each other using a variety of sensing methods.

Sipotek offers a line of automatic optical sorting machine that can also be used to do automatic sorting. The optical sorting machine product line offers users flexibility over a wide range of parameters that can be measured as well as sorting machines that are designed specifically for certain objects such as screws, rivets or bolts. One sorting system from the optical sorting machine product line is designed to discriminate metallic objects based on hardness. Each optical sorting machine offers powerful technology to any production line.

Today we will talking about simple what should the automatic optical sorting machine manufacturers include in the classification system?

Sipotek Visual Inspection Machine 7

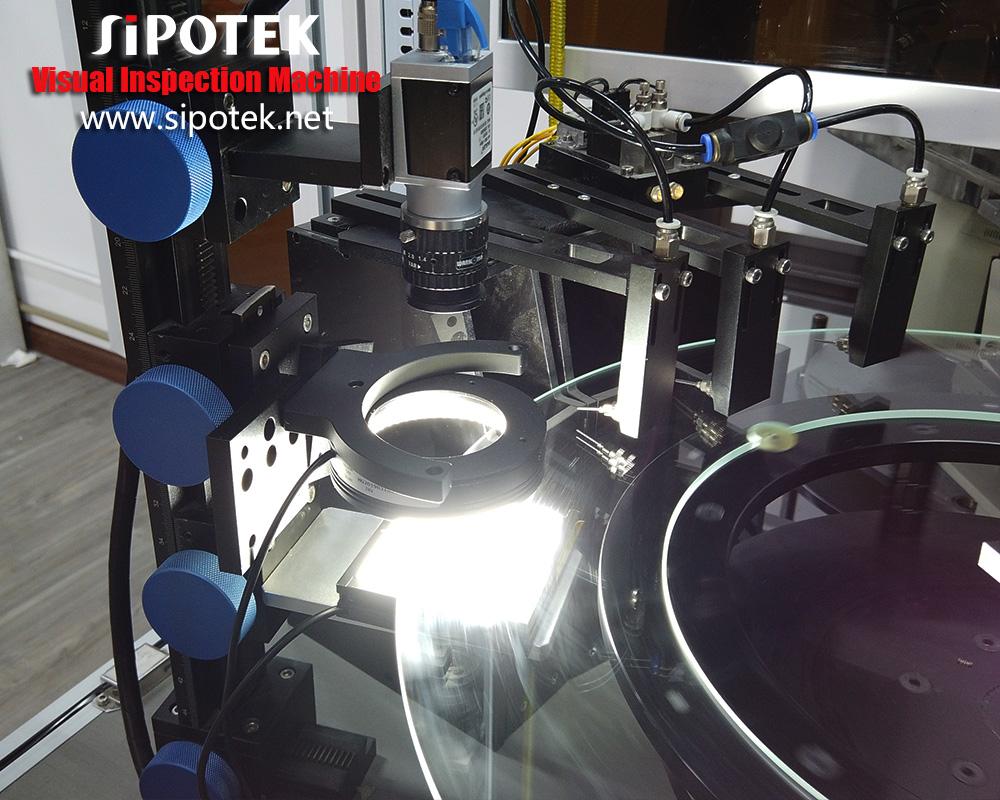

Achieving the perfect visual inspection machine requires the synchronization of many elements.

To create an ideal visual inspection machine it is necessary to place all the necessary elements and functions so that they can do an efficient job and a correct classification. That is why the optical sorting machine manufacturers must have a delicate classification system available on their machines, this is a vital element for the operation and success of these inspections.

Although a machine is formed by infinite elements, in the selection area only a few are decisive.

It is important that there are a set of related elements and that they work in a synchronized way to ensure that all revisions can be successful. Although naming all the parts necessary for the optical sorting machine manufacturers to create the perfect visual inspection machine is a rather complicated task, since many elements coexist within them, but if we talk about the classification system, we can say that there are a few.

Elements that form a classification system.

The most common elements that make up the classification system of such a machine are:

Sensors

The sensors are sophisticated machines that are responsible for collecting certain data related to the frequency spectrum that can be thrown by the incidence of certain elements with which the inspection is performed. As a result of the incidence of light on the objects to be reviewed, and the result of the wavelength that it shows the reader. Through the sensors other elements that make up the machines can be controlled, since these are the ones that determine if an element is suitable, and also where they should go, if towards the container of the elements that did not pass the test or the yes.

To be

Lasers are more specific in their tasks, since they depend on the information that the material or product can provide to the machine of the inspection, since this, through the incidence of light, can ask for some answers that are translated into data used to make relevant comparisons to classify products.

Lasers have been in charge of reaffirming the task of the machines to carry out non-invasive inspections, since they do not structurally damage any of the elements they review. They may be able to review inorganic and organic materials.

Cameras

The cameras fulfill the function of capturing the images of all the elements that pass through the machine, they are able to inform about the physical characteristics of a material, dimensions, shape and even color (if high resolution cameras are used).

These are usually strategically distributed throughout the channel, and in this way they can capture all possible angles of the product, so a much more accurate comparison is made, an ideal comparison.

These are the basic elements that all optical sorting machine manufacturers include in the elaboration of their machines, there are even some that use the mixture of these so that their machines are more efficient than many.

For more about optical sorting machine,you can pay a visit to sipotek at http://www.sipotek.net/machines/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net