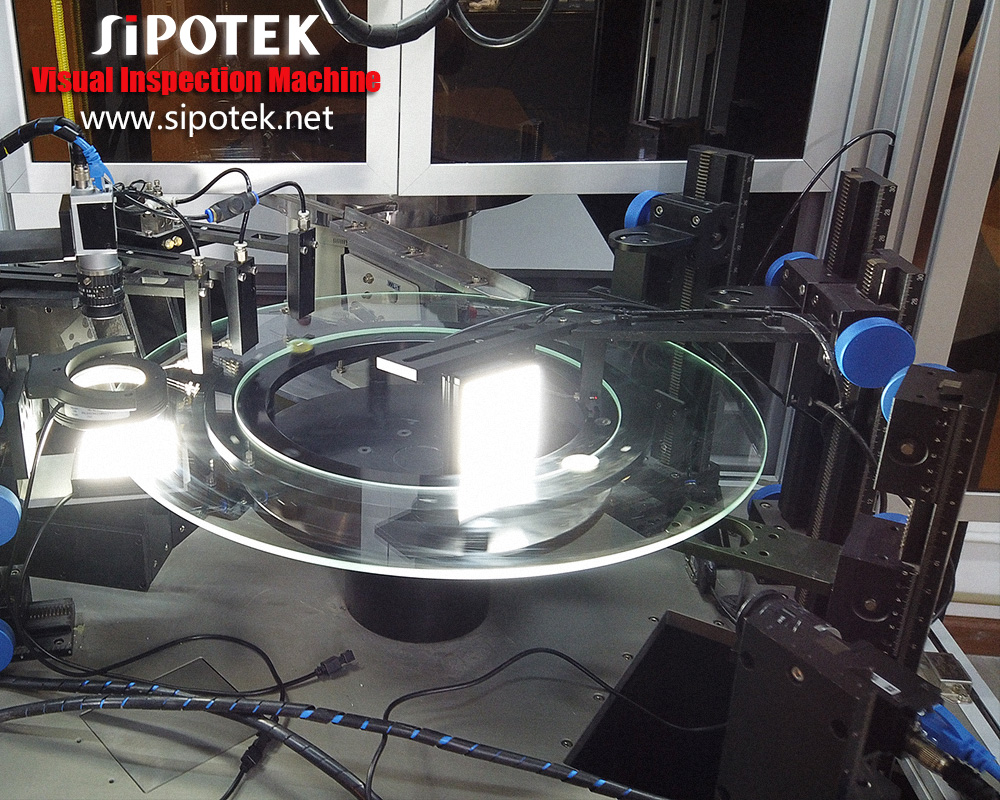

An automated inspection system can help enhance inspection and provide a consistent overview of the production line, identifying and classifying defects for future reference. Machine vision cameras are the main working basement for an automated inspection machine. Cameras are used to capture image data from an examined object or location for a number of imaging applications such as machine vision or factory automation.

Before we choose an automated inspection system, we should consider below information.

- Q: How many workers can be replaced by the inspection machine?

A: The machine performance differs from the products to be inspected. For small items, it can replace 8-10 workers; For big items, it can replace around 3-5 workers. The key point lies in the reliability and stability of the machine. Generally, the inspection work by machine will be more stable, while the human inspection work will be affected by mistakes and fatigue.

- Q: What’s the inspection range?

A: Our machine can be applied in a variety of industries. We have experience in precision hardware, magnetic parts, plastic accessory, rubber parts, zippers, labels, character recognition, pharmacological stopper, etc.

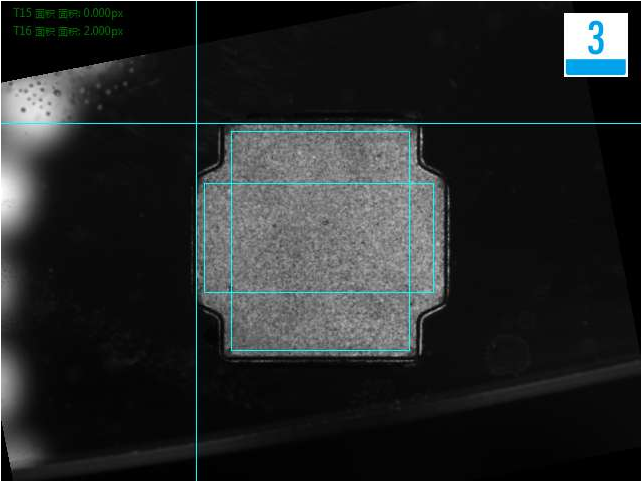

- Q: What’s the correct percentage of the inspection sorting machine?

A: When sorting the qualified products, the accuracy percentage can reach 99.9%, but actually it’s reaching 100% certainty most of the time. The feeding performance depends on the stability of both product material and production. If a QC staff can inspect 97 pieces qualified items out of 100 pieces, the machine can generally inspect 95 pieces. The material stability and lighting will influence the inspection. What we can be sure is that the qualified items are all correct inspected as OK.

- Q: What is the delivery time?

A: The standard machine will be ready in 15 work days.

The delivery time varied from the place of delivery.

The customized machine will depend on the specific solution.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/