Vision inspection is implemented to detect product defects such as scratches, dirt, foreign material and other physical defects. At factory automation sites, vision inspection technology are mainly used for ensuring quality control to achieve a 100% OK degree. Traditional eyesight-based inspection by human for checking thousands of products can lead to mistakes, such as overlooking defective products. Therefore, a visual inspection system that with image-based processing systems coming with extensive inspection tools and sophisticated algorithms can withdraw such mistakes by human eyesight-base inspections. Take MLCC chips for an example. There are multiple models available in MLCC products, such as ceramic chips, caps, resistors, capacitors, and most of them are very tiny and exquisite, even a human can not find its defects. By using an optical vision inspection system can solve this matter.

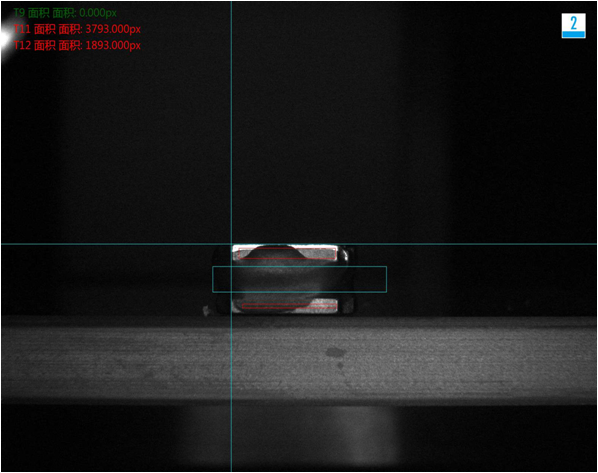

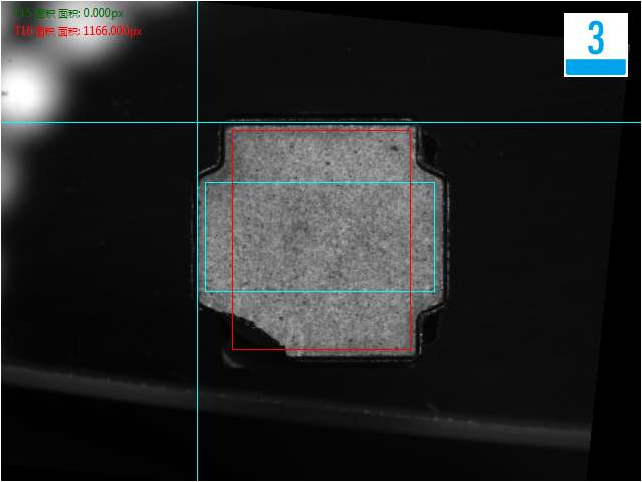

Sipotek researches and develops machine vision technology as its main future purpose that based on imaging technology and inspection software systems. The machine developed by Sipotek for multilayer ceramics will have an automatically system from the feeding to the output delivering. Only one operator is enough to control multiple machines. The machine will start running from a hopper where a large quantity of chips are pulling inside. A sensor is set to get and deliver the feeding signals. Chips will be rearrange by a vibration bowl until they were rotated to a linear belt one after one waiting for the next station of inspection. A glass rotary plate is installed right after the vibration station. Chips, resistors, or capacitors will be transported on the glass plate and waiting to be photo taken. Sipotek develops its own patented inspection software systems. When the products were delivered to the fixed station for image shooting. The signals and data are transmitted and collected by the software system. With return to signs that controls the next moving. 4 sides or 6 sides inspection determines the number of the inspection station and the number of cameras we will use. For capacitors, we usually apply a 6 sides or faces inspection. That means 6 cameras are needed to shoot 6 faces of the products.

What do Sipotek MLCC vision inspection machine inspects? There are two indexes are usually applied in any inspection projects, one is dimensional measurement, the other is surface defects, or we call appearance defects. For dimension inspection, either length, width, height, or thickness, gaps, terminations are measured by point to point, or line to line. For defects inspection, we will analyse the chipping, broken, cracks, unexpected holes, dots, scratches, miss-plating, body impurities, etc.

The inspection systems and mechanisms are different when applied to different products. So we will always do customizable machines that cater to each customer. We aim to provide the most suitable machines for each company so that they can use the machine to create the utmost profits on a lower cost consumption.

Established in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Email: [email protected]

Manager: Suzy Su

Mobile Phone + 86 18666216027

Email : [email protected]

Website: http://www.sipotek.net/

Website: https://www.topvision.net