What do you need to consider if you prepare to purchase a machine vision inspection equipment to check your product quality? We have a list of the questions that can help you understand the requirements of the inspection machine.

1.Inspection technique

Machine vision inspection is widely used in manufacturing process either for online or offline. People will ask what’s the differences. For online inspection, also called as in-line system, it’s much related to the production line and the vision inspection system will be installed into the production line during a product is being produced. It is used to detect raw material or half-finished products before they go to assembly line. For offline inspection , it’s usually used for final product quality detection before packaging process. In online process, the steps are almost automatic, no human contact, while in offline process, human need to manually input a large quantity of products to the feeder and place the collection boxes to collect NG or OK products under the machine output ports.

2.The estimated inspect stationary

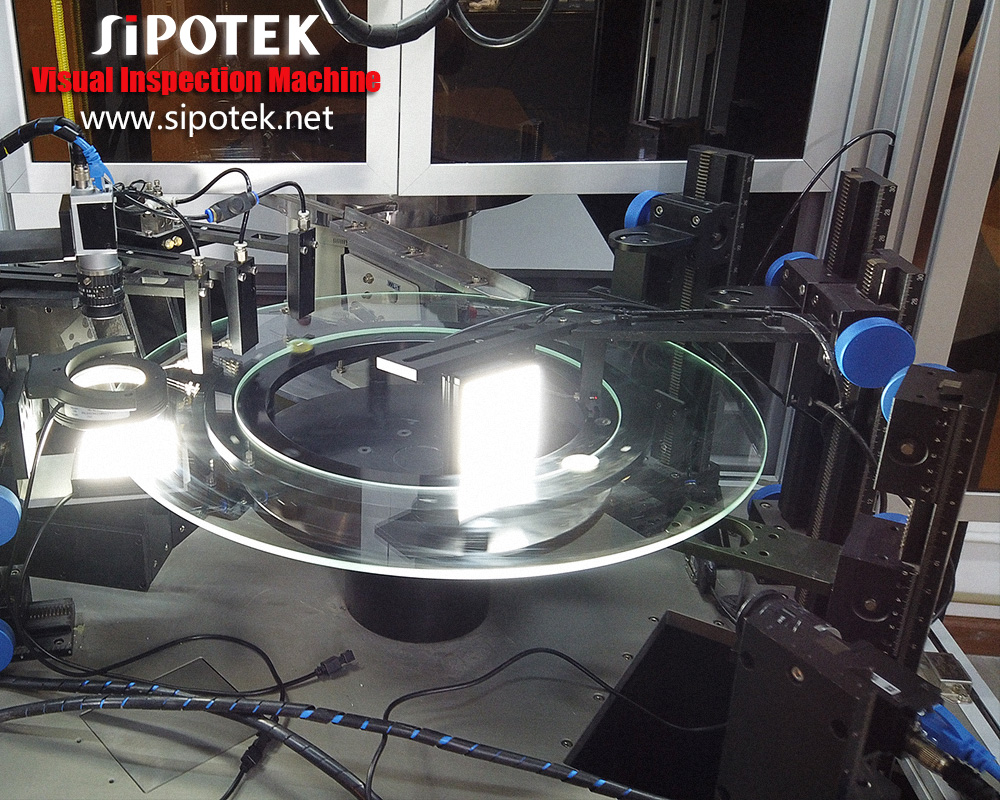

Each company manufactures different kinds of items. The vision inspection machines are always custom-made. There are several inspection stationary for choose. Glass rotary plate, separation wheel plate, one-click platform form, XYZ servo platform, roll carry tape. We will choose the correct platform according to product size, shape, weight or material.

3.Inspection efficiency

Productivity indicates the capability that a factory can produce the quantity on a daily or monthly basis. Generally, the smaller size of the product, the faster speed of the inspection. The inspection efficiency need to be consistent with company productivity. We will make the mechanism suitable to run the products at an acceptable speed to meet the productivity. According to our cases, the speed range will be 100-1200 pcs when the product size is within 40mm.

4.Compatible product models

The machine system will be customized design according to products. Our vision system can be compatible in 2-3 models of the product if the features of the product are similar. For example, they have the same shape, only one is small and the other is bigger. In this case, the size difference should not be extend 2-3mm.

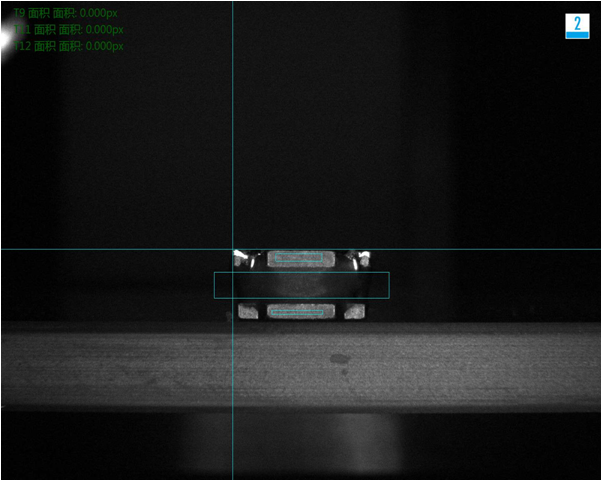

5.Dimension measurement

If you need to check the product size, we should check the drawing of the products. We will ask customer to give a detailed drawing with highlighted marks of the sizes they need to inspect. Currently we can measure the following:

1)Circle dimension measurement (Inner and outside diameters and balance, thickness);

2)Line to line distance (Suitable to measure regular rectangles in the length, height, width, step and step width);

3)Dot to dot distance (Suitable to measure bur size, dot to dot size);

4)Area measurement (Suitable to measure specific area of parts,decide good or not);

6.Inspection accuracy

The accuracy is related to the tolerance of the product size. For example, if a brass tube has a diameter of 9.2mm ±0.02, the tolerance is either +0.02mm, or -0.02mm. That means when the diameter is measured to 9.22 mm to 9.18 mm, the size is correct. We will programme the software system according to the tolerance so as to make the accuracy more correct. Currently most of our cases can reach a 0.01 repeatedly accuracy.

About us

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186 1718 2707

Email: [email protected]

Website: http://www.sipotek.net/machines/