Dimensional measurement is a type of appearance measurement ranging from length, width or center circle, dot to dot, line to line. Generally, customized solutions can be created and specialized hardware can be found for virtually every type of measurement outline. There are several types of dimensional measurement in quality control application.

Hand tools – Although they may be the most basic type of measurement equipment, hand tools remain useful for certain applications. When all you need is a simple solution, a fixed caliper or ring gauge can be both the most effective and the most affordable option. Hand tools also are highly portable, especially when compared with the more high-tech equipment types.

Coordinate measuring machines – Also known as CMMs, this popular type of measurement equipment takes the physical measurements of an object and converts them to a digital format. Although CMMs produce relatively fast and accurate results, they are not right for every application. Because they use a touch-based sensor, CMMs cannot be used with objects that have an elastic surface or are otherwise too delicate to touch during the measurement process.

Optical comparators – This type of equipment projects light onto an object with a screen behind it. The edges of the silhouette are measured to determine the length and width of the object. The method can also be used to compare an object to a desired standard by using a physical overlay.

Structured light scanners – These are a good option when three-dimensional measurements are required and the object cannot be touched or has a lot of freeform geometry. Dimensions are obtained by projecting a pattern of light onto the object and measuring the distortions caused by its surface characteristics.

Laser scanners – Another type of non-contact measurement method uses lasers. Similar to structured light scanners, the reflection of a laser point or line is used to measure the distance to the surface of an object. The resulting point cloud is used to create a 3D rendering that can be employed for reverse engineering, dimensional inspection, or other applications.

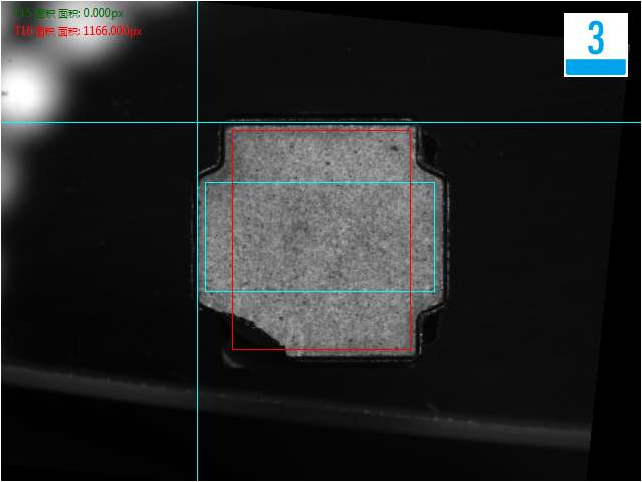

Vision systems – This type of measurement instrument employs high-resolution video to gather images that are processed with integrated software. Vision systems are often used in quality control applications that require a high level of accuracy and precision while producing fast and reliable results.

Sipotek Visual Inspection Machine 13

No matter how we choose the methos to perform dimensional measurements, the purpose is to decrease incorrection and increace qualified rate and to help provde a more safety place for manufacturing plants.

About us

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186 1718 2707

Email: [email protected]

Website: http://www.sipotek.net/machines/