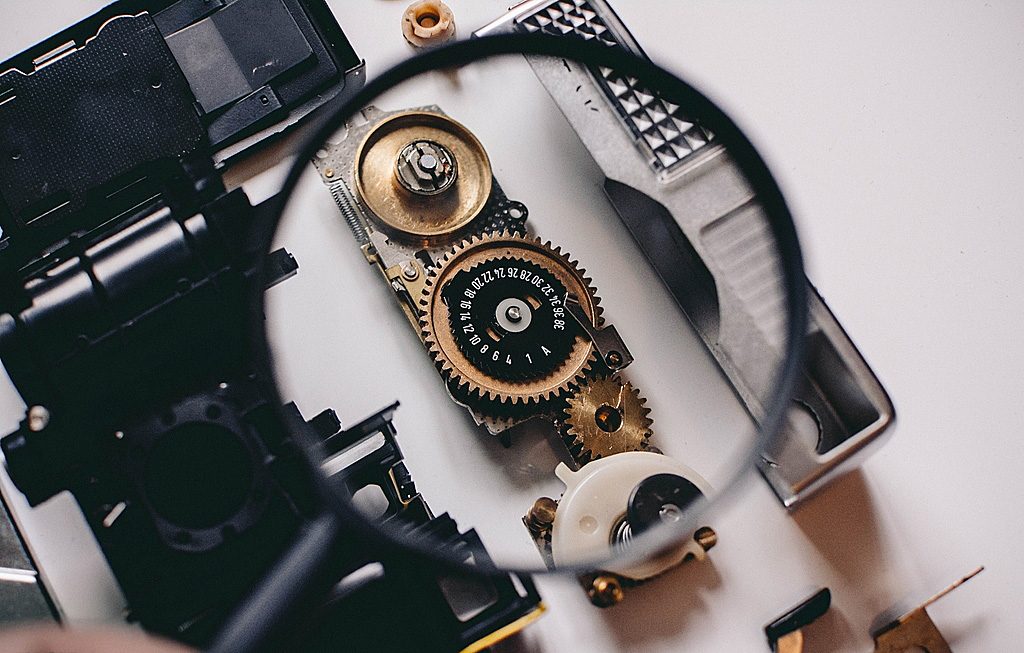

What’s the problem concerned you most during quality control process? The crack, damage, scratch or the burr? I think all of these are common defects of negative products. Some defects are easy to be discovered. Quality control workers can easily find them by naked eyes and pick out. However, some of the defects are not easy to find especially the tiny burr of the edge, the dimension of the product and the inner defects, etc.

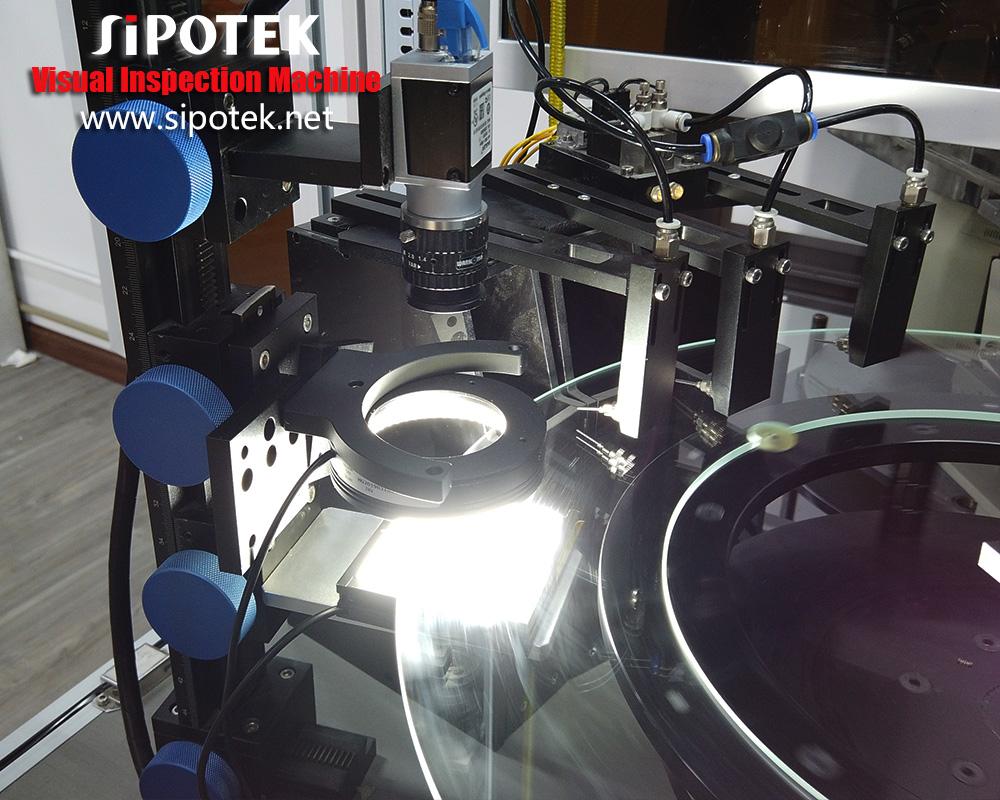

The vision inspection is made to solve these problems and make the inspection work more fully. Machine vision is the main technology that used in vision inspection system. The concept comes form the idea of human eyes. Through industrial cameras capturing clear and visible images of the inspected object, the system can make contrast to the qualified parameters so as to determine which one is qualified and which one is not.

Machine vision inspection equipment is an important and indispensable equipment for modern industrial production. It is widely used in various kind of fields. So it brings to the question. What are the classifications of Machine vision inspection?

Let’s find them in the following description.

Machine vision inspection is currently divided into 3 main categories, Main function, Detection technology and Installation carrier.

- According to function, machine vision inspection is classified as, Positioning, Defect inspection, Dimension measurement, Counting/missing detection, Feeding and etc.

- According to detection technology, machine vision inspection is classified as, Three-dimensional machine detection technology, Mottled detection technology, Scale measurement technology, OCR technology, Color recognition technology and etc.

- According to the carrier of its device, there are Online camera vision inspection system and offline detection system.

Machine vision inspection equipment is non-contact, high precision and automatic. Compared to general image processing system, machine vision emphasized the accuracy and speed, as well as the reliability in industrial on-site environment.

“Improve safety in your plant” is the concept we hold. In traditional manufacturing plants, workers are staying at the production line more than 8 hours a day during the pre-production production and post production processes. Thanks to automaton development, the machines help workers to operate the production automatically with efficiency in more safely conditions.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/